Few inventions rival the personal computer. Not only is it possible to seamlessly communicate with people across the world, but you can also run an entire company from a laptop.

Computers are nothing without the right computer chips, though. Companies have spent decades optimizing the manufacturing process for microchip production.

Understanding how these computer parts are made can provide valuable insight into one of the key processes that make computers run. The good news is that it’s not as complicated as most people anticipate. Let’s explore the key information you should keep in mind.

Table of Contents

It Starts With Sand

Many people are unaware that the first step in computer chip production is the use of sand. More specifically, it involves using silica sand. This is composed of silica dioxide and will serve as the foundation component of computer chip production.

Purification

The silica sand will then be purified to produce a silicon ingot. This is a cylindrical segment of pure silicon that’s created in a laboratory. Electronic-grade silicon undergoes a large number of filtering and purification procedures.

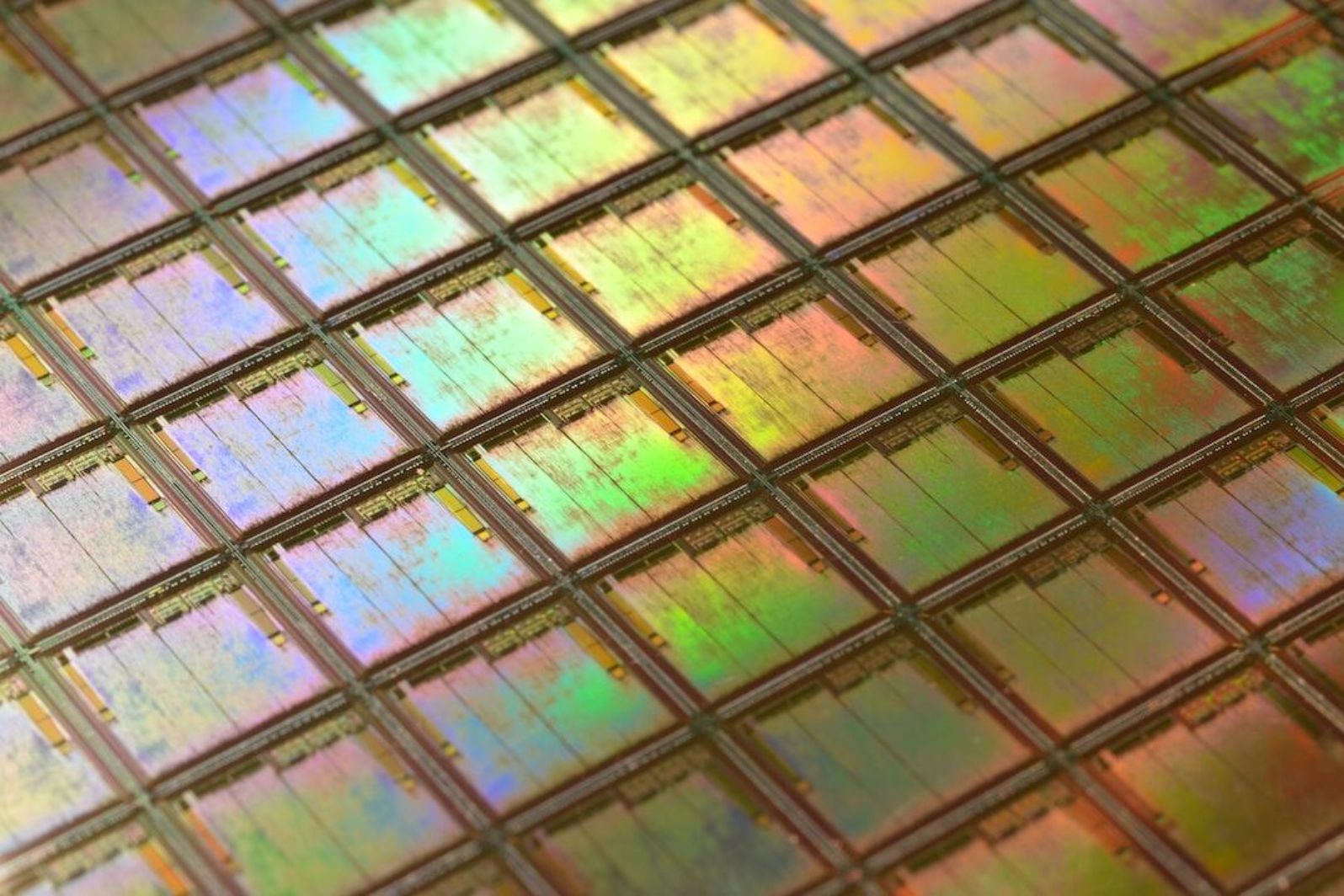

Afterwards, the manufacturer will cut the silicon into rectangular wafers that will eventually become computer chips. The size and shape of the wafer are influenced by the chip’s intended use.

As you might expect, large computer chips will require larger segments of silicon. The wafers’ rough edges are then smoothed until they’re flat. This allows electrical signals to pass uninterrupted over its surface.

Wafer Refinement

Once the wafers are cut and shaped, they’re then polished and cleaned before the manufacturing process continues. The manufacturer will then add multiple layers of different materials to the surface of the wafers. These layers serve various purposes, including isolation and creating electrical paths on different segments of the chips.

The Use of Photolithography

For those unfamiliar with this term, it involves applying a thin layer of photoresist and using light-sensitive material to transfer patterns onto substrates. Then, the wafer is exposed to light by using a mask with a design pattern.

Exposed areas of the photoresist are developed, creating openings that align with the desired pattern. Once this process is complete, the wafer will etch the wafer and transfer the intended design to the substrate.

Ions and Doping

Doping involves applying ions to the silicon wafer to manipulate its conductivity. This occurs after the exposed photoresist layer has been removed.

This reveals both the impacted and unaffected material. The doping segment of the manufacturing process is highly sensitive to error. Even a minor mistake could lead to many complications.

Etching

Using reactive chemicals, the manufacturer will remove a thin silicon layer from the chip’s surface. The intended depth of removal will influence the rate at which the manufacturer applies the chemicals.

Engineers can repeatedly use this method to create complex patterns across different types of chips. For example, they might modify the way they etch to create memory chips instead of processors.

Electroplating

At this point, the computer chip is nearly finished. It’s then covered in an insulating layer before being perforated with three holes.

Electroplating is the process of applying copper ions to the surface of the chip. This creates a layer of copper on top of it. It’s then cleaned away, leaving copper deposits in the three perforations.

Layering Interconnects

Computer chips contain a large number of interconnects, and many of these are only a few atoms thick. They contain wires that connect different types of electrical components.

Each wire will have specific functions and are compatible with each other, allowing them to communicate. This interconnectivity allows the chip to function like a processor.

Testing

It’s essential to thoroughly test each chip before packaging. Without the right level of testing, the manufacturer risks severely damaging their reputation.

This could make it difficult for them to secure contracts in the future. A key testing method involves slicing wafers into miniature squares called “dies.” Each die has millions of transistors.

If issues arise, the manufacturer will attempt to pinpoint the root cause. They can then take the necessary steps to resolve the issue. Depending on the circumstances, these problems could sometimes take weeks or months to figure out.

Finding Companies for Microchip Production

If you’re looking to outsource microchip production, there’s no shortage of companies to choose from. However, not all of them are created equal. It’s best to research online before making your decision so you know what to expect.

Otherwise, you risk choosing someone who can’t meet your needs. Keep an eye on how they respond to negative feedback, as well. Never hire a company that gets aggressive or defensive toward criticism.

Do they often work with clients like yours? This is a crucial attribute to consider, as they might not understand the nuances of your project. Their pricing is another attribute to keep in mind.

It’s best to avoid the cheapest companies you find. These are likely to fall short of your goals. This doesn’t mean you need to spend as much as possible, though. There’s a point of diminishing returns regarding what you spend on microchip production.

Instead, you should look for companies in the middle of the industry’s price range. This will help you get the best results without stretching your budget.

Check to see if they offer special services you can leverage. For example, some manufacturers have experience working with patterned silicon wafers.

Using resources like https://www.silybwafers.com/ will help you better understand the utility of this design option. With enough due diligence, you shouldn’t have an issue finding the best choice for your situation.

This Process Changed the World

Without microchip production, we wouldn’t have the abundance of useful electronics we have today. Communication couldn’t occur at the same pace, and many contemporary innovations would have been impossible. The info in this guide can help you appreciate the utility computer chips bring to the world.

Looking for other tech info that can help you out in the future? Our blog has plenty of articles like this one you can benefit from. Be sure to check it out today!