With the dawn of automation in industries comes the demands of accuracy and speed in order to remain competitive. This is why now, more than ever, there is a need for innovation in automation. Proximity Sensors have become industry staples for precise monitoring, dependable detection, and efficient processes in manufacturing, logistics, and robotics. For businesses looking for dependable solutions, Omchele offers a range of B2B proximity sensors for a multitude of industries. Find out more about the proximity sensors by Omchele here.

Table of Contents

Proximity Sensors in Commercial Automation: What are They?

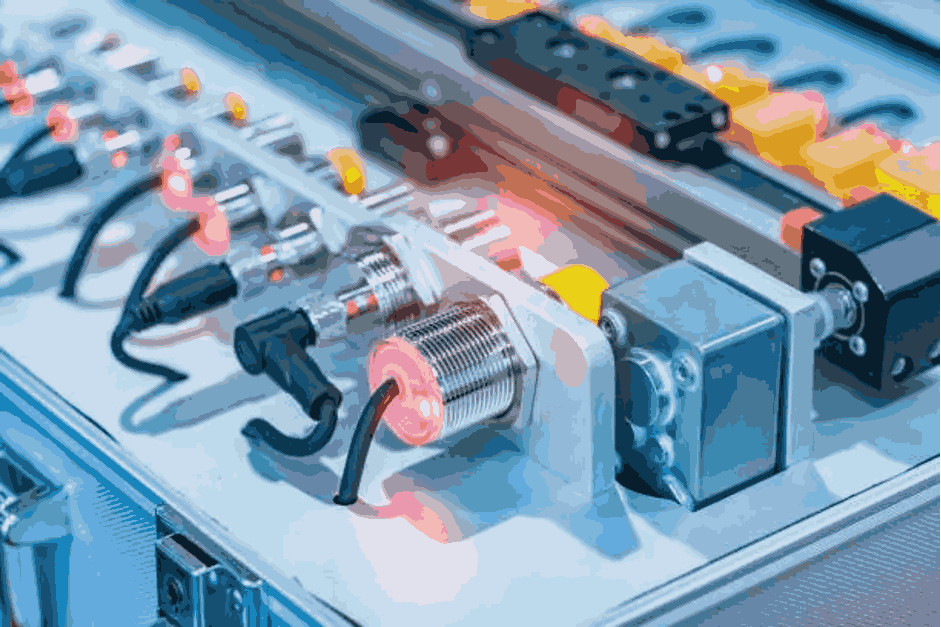

A Proximity Sensor is a device that can sense the presence of an object without making contact. They can also detect an absence of an object without contact. Unlike the mechanically-operated switch which is a contact device, proximity sensors are non-contact devices which make use of electromagnetism, capacitance, and even light. With these non-contact methods, the devices can ascertain an object. This approach decreases contact issues and inaccurate readings which is why it is ideal for industrial use.

The addition of proximity sensors offers b2b companies a way to enhance process control, equipment monitoring, and safety protocols. From assembly lines to robotic arms, these sensors help maintain continuity, preventing problems and overspending. Omchele sensors, for instance, are well regarded for their enormous, highly sensitive, and durable proximity sensors.

Key Types of Proximity Sensors

Each type of proximity sensor is tailored for a particular industrial use:

- Inductive Proximity Sensors: An inductive proximity sensor detects metallic objects within a confined space and is said to be one of the most useful sensors for detecting proximity for industrial and automotive structures that have dust, dirt, and moisture.

- Capacitive Proximity Sensors: These sensors are able to measure changes in capacitance and are able to be utilized within the packaging, as well as food processing sectors.

- Photoelectric Sensors: These sensors are able to be utilized within the robotic arms and conveyor systems.

- Magnetic Proximity Sensors– These sensors, also referred to as reed switches, detect and respond to magnets and are widely utilized for position sensing, door used monitoring, and security.

Omchele supplies a broad range of these sensors which allows B2B companies to choose the products that best meet their needs. Check Proximity Sensors. And, the full range of sensors would best serve B2B operations.

Benefits of Proximity Sensors for B2B Companies

There are various ways that B2B operations would be improved by including quality sensors:

- Greater Accuracy and Streamlined Processes: Erosion of efficiency as a result of unintentional discrepancies becomes minimal, as proximity sensors enhance the precision of production tracing objects.

- Greater Mechanical Durability: For both machinery and sensors, elimination of mechanical sensing contact translates to minimal wear.

- Regulatory Compliance: The use of sensors to accurately pinpoint danger zones helps in avoiding accidents and adhering to compliance in industrial and operational safety regulations.

- Enhanced Sensor Functionality: Forgetting incorporated systems in the tactical operations of industrial systems does not require high levels of engineering. They are easily adaptable in various fields such as automotive, electronics, packaging, and robotics in assembly lines or automated warehouses.

Omchele shares address the needs of companies looking to optimize production processes and improve business performance by delivering effective solutions that align within the available frameworks. Operational effectiveness is guaranteed.

Industrial Applications of Proximity Sensors

Omchele’s sensors or the remote entry systems have become crucial components to the smooth walking of the entire processes of an Industry. The major uses of the sensors are listed as follows:

- Automation of manufactory processes: Monitoring the assembly of parts along the assembly line and confirming that parts are properly placed within high-speed production streams are the sensor use applications.

- Robots: Providing distance information helps to use sensors as rangefinders for purposes of movement control, objects collision avoidance, and cooperation with other robots.

- Self-controlled machines: Proximity sensors control conveyor systems, individually or as a part of a logistic and packaging systems to control the flow of products, their jams, and cohesive functioning.

- Product inspection: The presence of parts, their monitoring and corrected location helps to reduce and maintain a stream of the defective products to fulfill the quality control considerations.

- Protection: Proximity sensors have useful applications for Industrial and workshop precincts by emitting alerts and commencing action controls when sensors perceive individuals in perimeter areas or when they are within hazardous conditions.

These sensors are made available as part of the business portfolio of the company. The sensors are responsive and are designed for easy attachment into the Industrial systems.

Selecting a Proximity Sensor for Your Application

In determining what proximity sensor best suits your needs, one must analyze the objectives, situational context, and sensor requirements for the solution:

- Sensing target Material: Inductive sensors are ideal for metal target sensors, while plastic, liquids and other non-metals can be easily sensed by a capacitive sensor.

- Distance Measurement Needed: The target detection range must fall within the configurations of the operational layout, otherwise, one must make accommodations for the automation objectives.

- Surrounding Noises: The sensor must be designed to survive tough conditions such as variations in temperature, humidity, as well as dust and other chemical possibilities.

- Reaction Speed: Production lines in this context must have sensors with quick response times, otherwise there is a risk of delays and faults.

- System Compatibility: Having both PLC and automation software as well as the control system promotes smooth installation and operational efficiency.

Omchela provides expert and tailored proximity sensor consultations, guaranteeing the optimal solution for each company’s needs and surrounding factors, including safety and efficiency.

Evolution and Emerging Hype in the Market for Proximity Sensors

With the advancement of industrial automation, proximity sensors are beginning to face new challenges:

- Advanced Sensors: Having proximity sensors with the ability to be integrated to IoT systems can enable real time analytics, system prediction and maintenance data.

- Miniaturization: Smaller sensors enable additional compact designs and improved integration into dense environments.

- Improved Resistance: Newer materials and designs further enhance exposure to challenging industrial conditions, increasing service life.

- Sustainable Operation: Performance remains unwavering for low-energy sensors, which aids in decreasing the carbon footprint of manufacturing.

In the context of B2B companies, the leap to next-gen proximity sensors will sustain next-gen operational efficiency and automation integration seamlessly. This is the continued logic of Omchele, which emphasizes precision, industrial reliability, and adaptability in developing sensor-based automation solutions.

In broader terms, proximity sensors have now become essential devices in contemporary industrial systems. As such, B2B companies which use Omchele become users of advanced, dependable sensors capable of increasing precision, efficiency, and safety of many facets- manufacturing, logistics, and robotics. Customers should visit Omchele for the complete array of https://www.omchele.com/fr/proximity-sensors/ to further enhance their industrial automation systems.