The automotive industry is known for its fast-paced innovation, and the key component of this dynamic process is prototyping. A motor vehicle must go through a process of design, development, and testing before it goes onto the ground. This process brings concept ideas into reality. Before large-scale production, prototype manufacturing is a crucial phase that enables engineers, and designers, to validate concept ideas, optimize design, and resolve any possible problem.

Table of Contents

The Importance of Prototyping in the Automotive Industry

The race to innovate is fierce, in an industry as competitive as automotive manufacturing. Automotive manufacturers are continually challenging the limits of technology to further enhance customer experience, safety features, and fuel economy. Using prototyping techniques, manufacturers may quickly adapt to new concepts or customer demands from the market. The design team can develop real-life models using this technique and make changes and modifications before going on to the next step stage of development.

Modern automobiles are more intricate than simple mechanical machines, and this complexity is dealt with in this prototype design process. Modern cars are integrated with software, electronics, and mechanical parts systems, Prototypes enable these systems to be tested for usability and efficiency ensuring a reliable product.

Concept Development: The Foundation of Prototyping

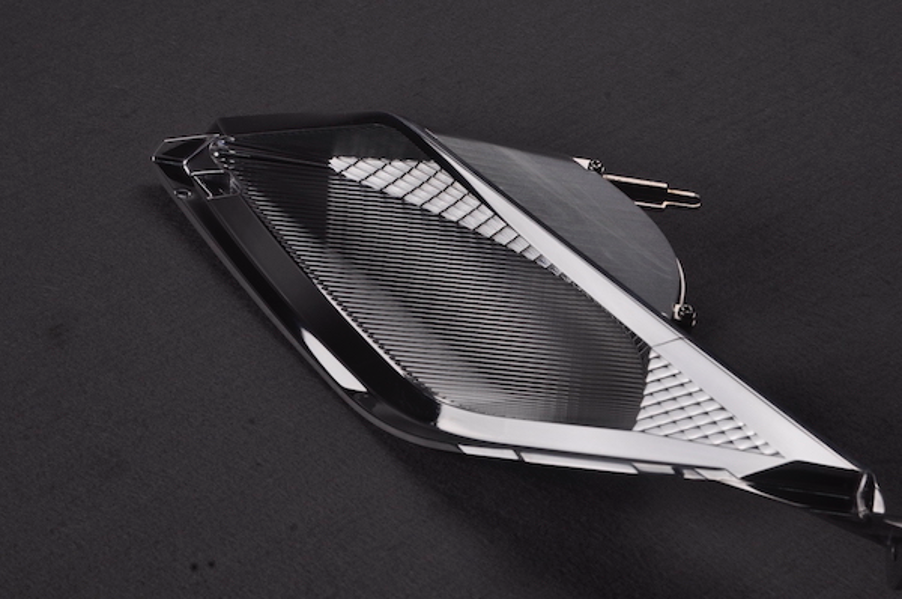

Developing a concept is the first phase in the engineering prototype design, where the vehicle’s initial idea is to draw out. Design engineers work on creating a concept virtual prototype of the automobile by using 3D modeling software like Solidworks, Inventor, and AutoCAD to demonstrate how different components fit together and then it allows designers and engineers to simulate these models to test various design elements to check the performance characteristics.

At this stage, prototypes can range from basic drawings or highly detailed models. Designers explore various changes in every component, Body, chassis, and engine to determine the best possible and effective layout. Prototype manufacturing mainly focuses on testing core components like the engine, or chassis frame, ensuring the design will function before moving into more complex systems.

Building the First Prototype

Once the initial design concept is finalized, the first real-life prototype needs to be manufactured. This is often called a ‘’mock-up’’ and is usually made from simple material like foam or clay. At this stage, the aim is not to produce a fully functional car but to create a model that provides an actual representation of the design. These early-stage prototype developments can help teams to better comprehend the car’s proportion and appearance.

The next step is to develop a fully functional prototype, often called an engineering prototype this prototype has all necessary mechanical, electrical, and software components. At this point, the real testing starts, and manufacturers examine how the vehicle works in real-life scenarios.

It takes meticulous collaboration between engineers, designers, and other supporting staff to develop a working prototype. Each part is tested separately before assembly into the full vehicle. This procedure ensures every component functions as intended, and reduces the likelihood of the issues that may arise during full-scale production.

Testing and Refining the Prototype

Perhaps the most critical stage of the prototyping process is testing. It includes putting the prototype in real-life scenarios to evaluate its functionality, robustness, and safety. In the automotive industry, this usually includes simulation of adverse weather conditions and crash tests. Etc. The information acquired from tests gives constructive feedback to engineers.

For instance, Crash testing is a strenuous procedure where prototypes are subjected to collision at different speeds to assess how well the car shields the passengers. Engineers assess how the frame collapses after the collision, how the airbags release, and how effectively seatbelts withstand collision.

In addition, prototypes are also tested to evaluate the performance in terms of fuel efficiency, engine performance, aerodynamics lift, and drag. Battery longevity and charging performance are important elements for electrical vehicles that need to be carefully taken into account. Engineers often encounter unexpected issues during these tests, which lead them to modifications into prototypes.

The Role of Digital Twins and Simulation in Prototyping

The significance of simulation in the prototype has evolved with the advancement of digital technologies. A ‘’Digital twin’’ is an electronic replica of the final prototype that allows engineers to evaluate different performance measures without the requirement of physical models.

These digital tools significantly accelerated the prototyping process. Which also allows the detection of potential problems and the execution of design modifications. By simulating various driving factors, material stresses, and load scenarios, engineers could improve their designs and minimize the requirement for physical prototypes.

Iteration and Continuous Improvement

The prototyping process is nonlinear. it usually takes multiple iterations, with every prototype model improving on the previous one. Continuous improvement is driven by feedback from testing different parameters as well as inputs from engineers, and designers. Every time the defect is identified, the prototype is modified, tested once more, and refined so the finished design meets all required standards.

This process ensures that the prototype is ready for production, and all possible problems have been resolved. This saves time and money by reducing the likelihood of recalls and failures in the finished product.

Finalizing the Prototype and Preparing for Mass Production

Once the prototype has undergone extensive testing and improvement, the last step entails the design ready for mass production. This is a crucial stage since large-scale manufacturing introduces its own set of challenges. Engineers are required to make sure the production process is more efficient, minimizing waste and maximizing the utilization of material.

A final round of testing is often performed on the final product to confirm that all components meet standards and safety criteria. After this, the vehicle is ready for large-scale production.

Conclusion

Prototyping is a crucial process in the automotive industry that converts concept ideas into functional vehicles. The journey of turning an idea into reality involves several steps, from initial sketches to a full-scale functioning model with each phase aimed at improving the design and its feasibility.

Engineering prototype and prototype manufacturing both are part of this process, which enables automakers to produce cars that not only meet safety and performance standards but also push the limits of innovation. Prototyping helps the automobile manufacturing industry to grow and offer consumers safer, more efficient, and modern technology vehicles.